HATS

2022년 01월 05일 2022-10-17 14:18HATS

DRILL & BLAST SOLUTIONS

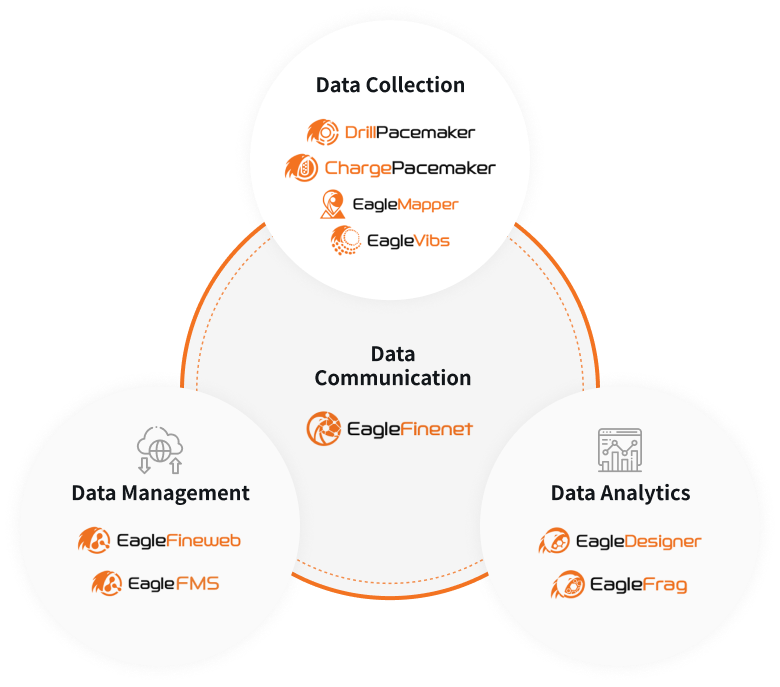

Hanwha As a Total Solution

Innovating the Technology of Drill & Blast

Convenient solutions from design to blasting

Enhancement of environmental safety with advanced monitoring network

Cost reduction through the latest equipment and innovative technology

2 Key Factors of Smart Mining

From Drilling services

to Total D&B services

Value Proposition

Hanwha's HATS provides the following four advantages

Real-time Monitoring

Cost Reduction

Operational Insight

Safe and Clean Workplace

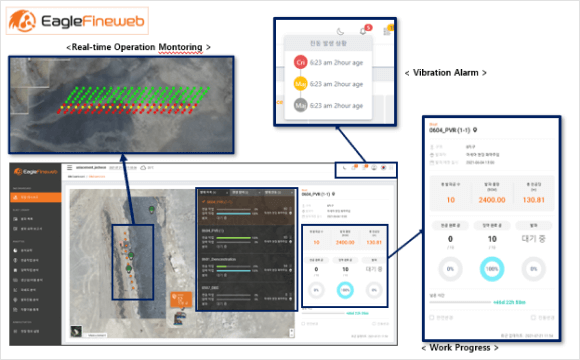

Key 1. Real Time Monitoring

1. Real time monitoring of field equipment/field operator

· Real time monitoring of field equipment/field operator

– Current work performance relative to total work plan

– Estimated work end time

· Efficiency of on-site operation management

– Dashboard alarms when on-site issues occur

① Work progress rate delay

② Blasting vibration/noise exceeded

③ Equipment failure

· Available on various mobile devices

– Cellphone, Tablet, PC, etc..

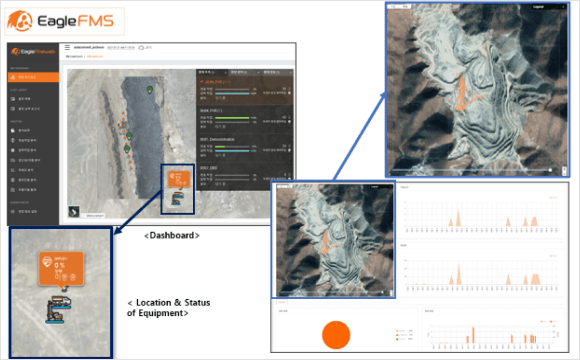

2. Real-time Field monitoring

· Provide information on the location of workers and equipment.

– Location, condition of the equipment.

– Equipment : Drill, MPU, Dumptruck, Watertruck, Loader, excavator, patrol car

· Provide on-site real-time production

– Automatically aggregating waste and resource production by detecting truck operation conditions.

– Automatic calculation of resource grade in production by storing grade data for each zone.

Key 2.Cost Reduction

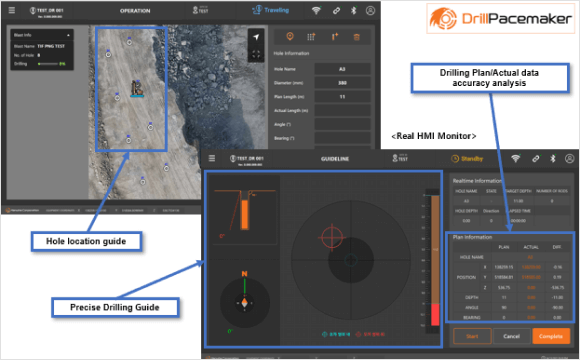

1. Improved drilling accuracy

· Optimize drilling with field data analysis

– No. of holes reduced through spacing optimization

· Minimizing drilling errors with sensors

– Prevention of over-drilling with accurate depth measurement

– Re-drilling work rate reduced by checking real-time drilling coordinates (Within ±5cm of coordinate error)

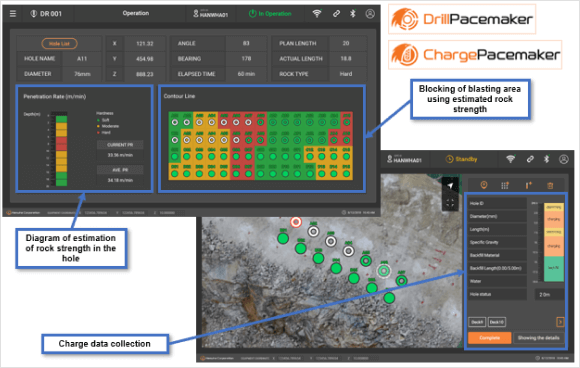

2.Optimization of explosives usage

· Selection of explosives considering rock strength characteristics

– Rock strength can be determined by using collected drilling data

– Estimation of rock strength by measuring pressure values during drilling

– Suitable explosive charge with specific gravity for rock properties

· Strengthening the management of explosives by collecting charging data

– Prevention of overcharge during charging operation

3. Minimize follow-up work

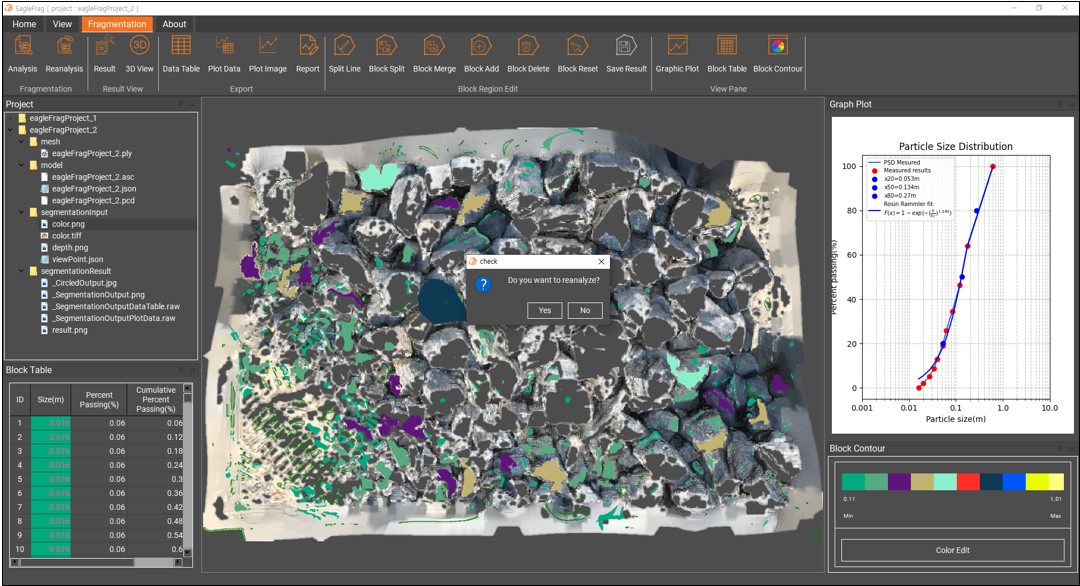

· Improve blasting particle size

– 3D fragmentation analysis provided

– Providing a unique crushing particle size estimation formula suitable for site characteristics

· Achieving the target fragmentation

– Optimal blasting design through data analysis

– Calculation of crushing particle size suitable for site purposes such as loading and transporting, crusher

Key 3.Operation Insight

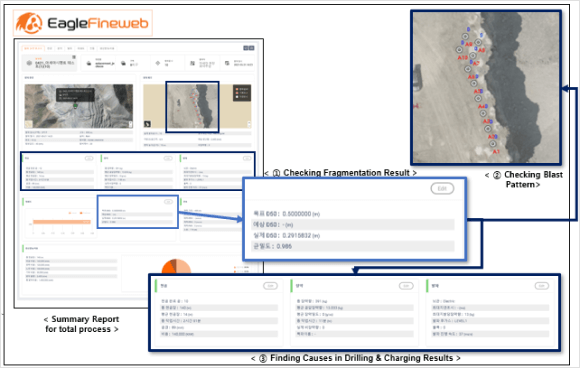

1. Total D&B Processes Report

· Database of all D&B processes – Automatic collection of on -site data and report

· Tracking and managing issues and results – Check issues in the result report – Possible cause analysis in job report

· Report offers – Drilling : Equip. inputs, workforce, drilling status, etc. – Blasting : Explosive used, charge amounts, work time, etc. – Vibration/Sound : Measurement location – Fragmentation Analysis: Fragmentation graph, particle size value, etc. – Production/cost: Cost of each operation, production volume, etc

2. Total management

· Real time management

– Real-time monitoring of the site information

– Able to use various mobile devices

· Statistical data

– Analysis and reporting of database

– Supporting site management

· Data management

– Web server for data storage and platform

– Total storage of pattern, process, and result information

Key 4. Safe and Clean Workplace

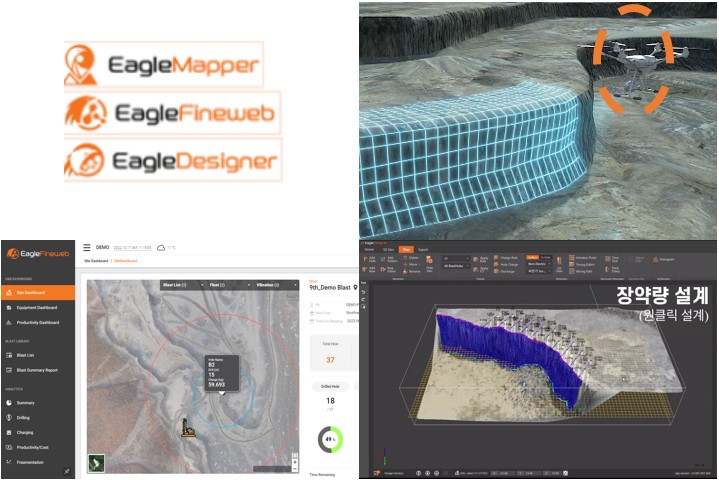

1. Blasting Design Based on Actual Terrain

· Blast designs reflects actual model, preventing scattering

– Acquisition of actual terrain information through drone mapping

– Drilling and charging design considering the actual free surface shape

2. Safety Review at the Blasting Design Process

· Safe distance indications and blast design sphere of influence predictions

– Provides flyrock distance and influence range of vibration/sound

– Indication of safety distance and sphere of influence in blasting design

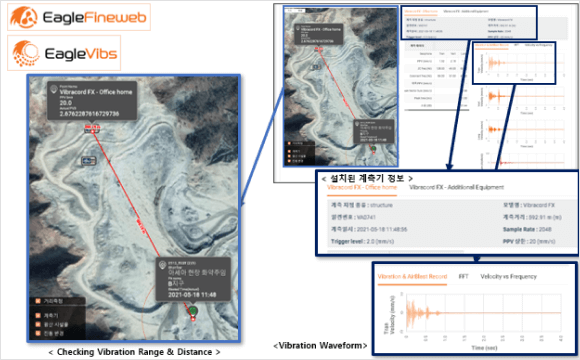

3. Vibration/Sound Monitoring

· Autonomous vibration/sound measurement

– Autonomous data collection when vibration &noise occurs

– Alarm occurs when vibration & noise exceeds the threshold

– Minimize workload of measurement management

· Prevention of civil complaints through vibration management

– Reconsidering blast design through the use of collected measurement

data, vibration influence zone and security object

· Automatically update site-specific natural vibration constant

– Reconsideration of explosive type